Автоматизированный пеллетный котел 100 кВт FOCUS с золоудалением и климат-контролем для домохозяйств и офисов

Автоматизированный пеллетный котел 100 кВт FOCUS с золоудалением разработан для эффективной работы с высокозольной агропеллетой и оптимизирован для бескомпромиссного отопления. Он оснащен встроенной промышленной пеллетной горелкой и системой шнекового золоудаления, что существенно снижает необходимость в ручной очистке и увеличивает интервалы между обслуживанием.

Пеллетный котел 100 кВт FOCUS с золоудалением: основные преимущества

- Максимальный зольник: предназначен для работы на высокозольном топливе, что обеспечивает высокую эффективность.

- Встроенная система шнекового золоудаления: упрощает процесс удаления золы и повышает комфорт эксплуатации.

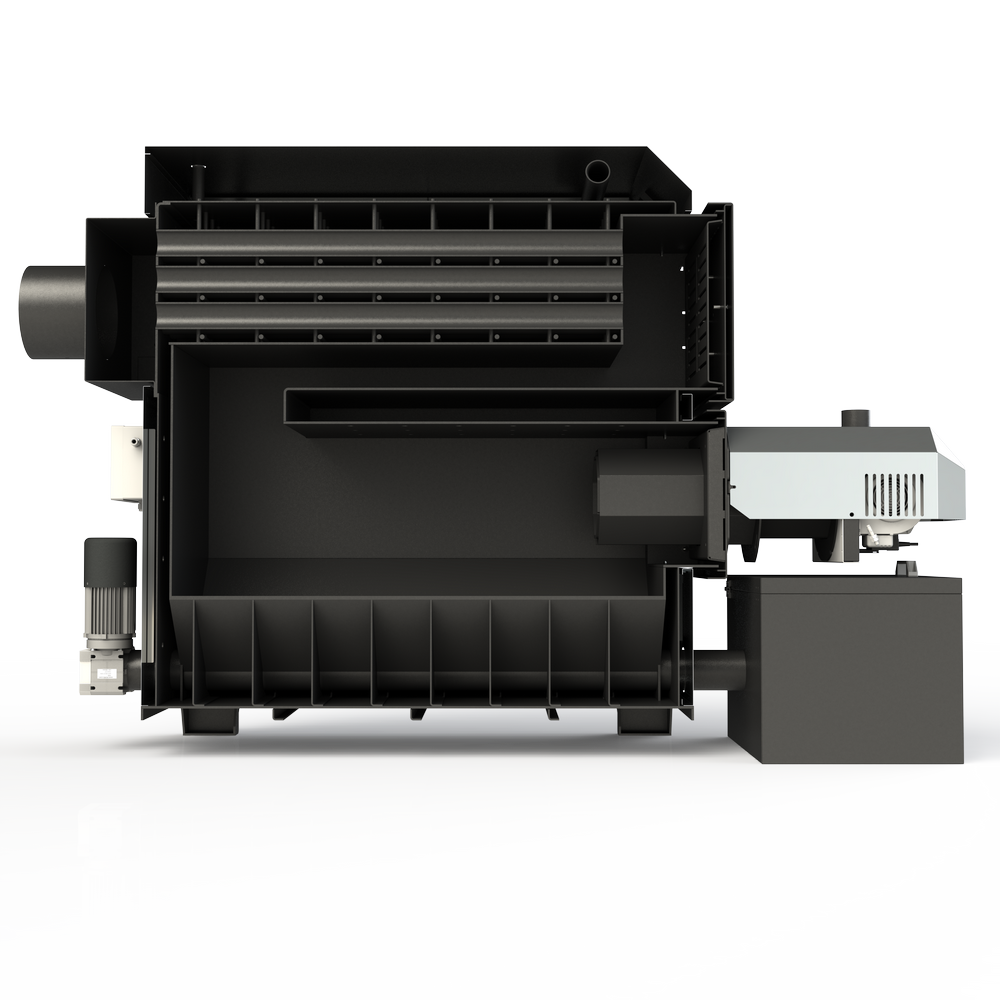

- Гибридная структура теплообменника: сочетает в себе пластиночный и жаротрубный теплообменники, что способствует эффективному теплообмену и осаждению тяжелых частиц.

- Удобное обслуживание: широкий люк и зольная камера перед дымоходом облегчают доступ для очистки.

- Защита от холодной обратки: возможность установки обвязки с трехходовым или четырехходовым клапаном увеличивает КПД котла на 30%.

Пеллетный котел 100 кВт FOCUS: конструкция и материалы

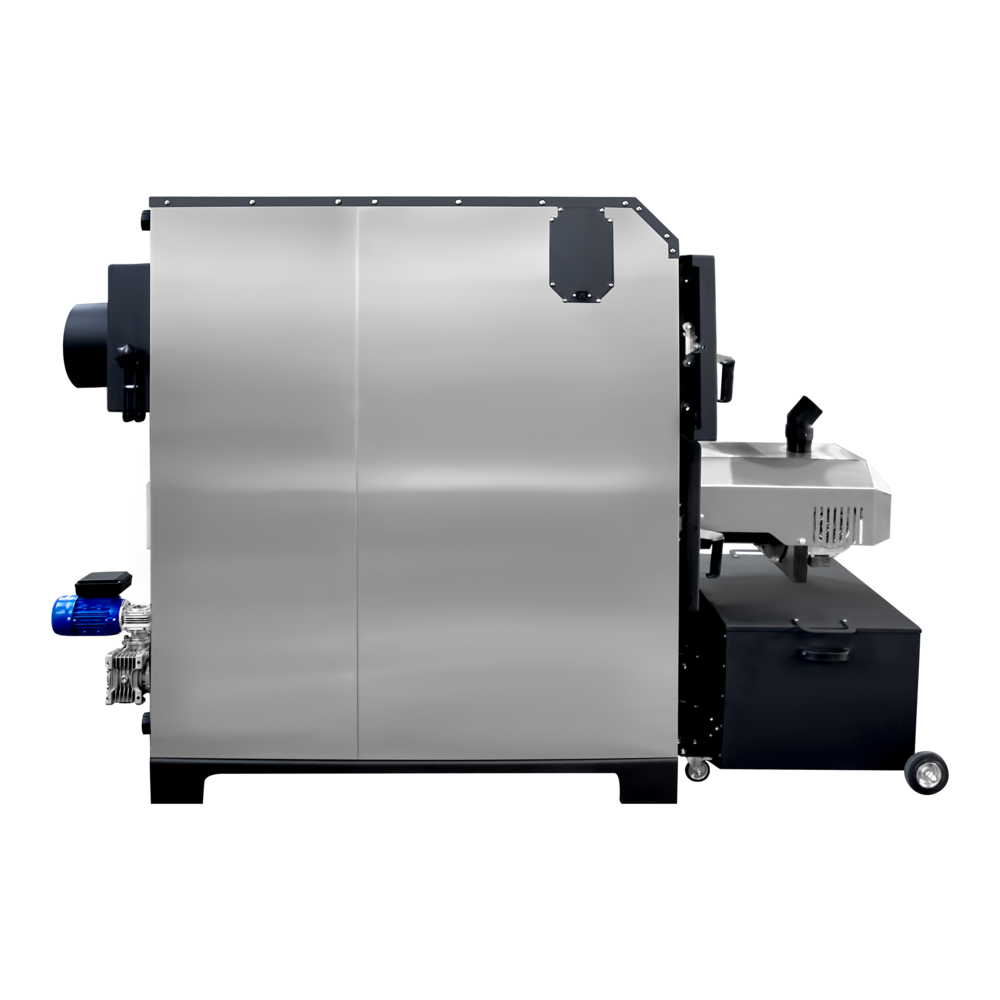

- Корпус из конструкционной стали: толщина стенок теплообменной части составляет 6 мм, что обеспечивает долговечность и надежность.

- Теплоизоляция: выполнена из базальтовой минеральной ваты толщиной 50 мм, что гарантирует высокую теплоэффективность.

- Нержавеющая сталь: кожух котла изготовлен из шлифованной нержавеющей стали AISI201, что обеспечивает защиту от коррозии и эстетичный вид.

- Система быстрого монтажа Victaulic: облегчает установку и соединение компонентов, снижая время монтажа и исключая необходимость сварки.

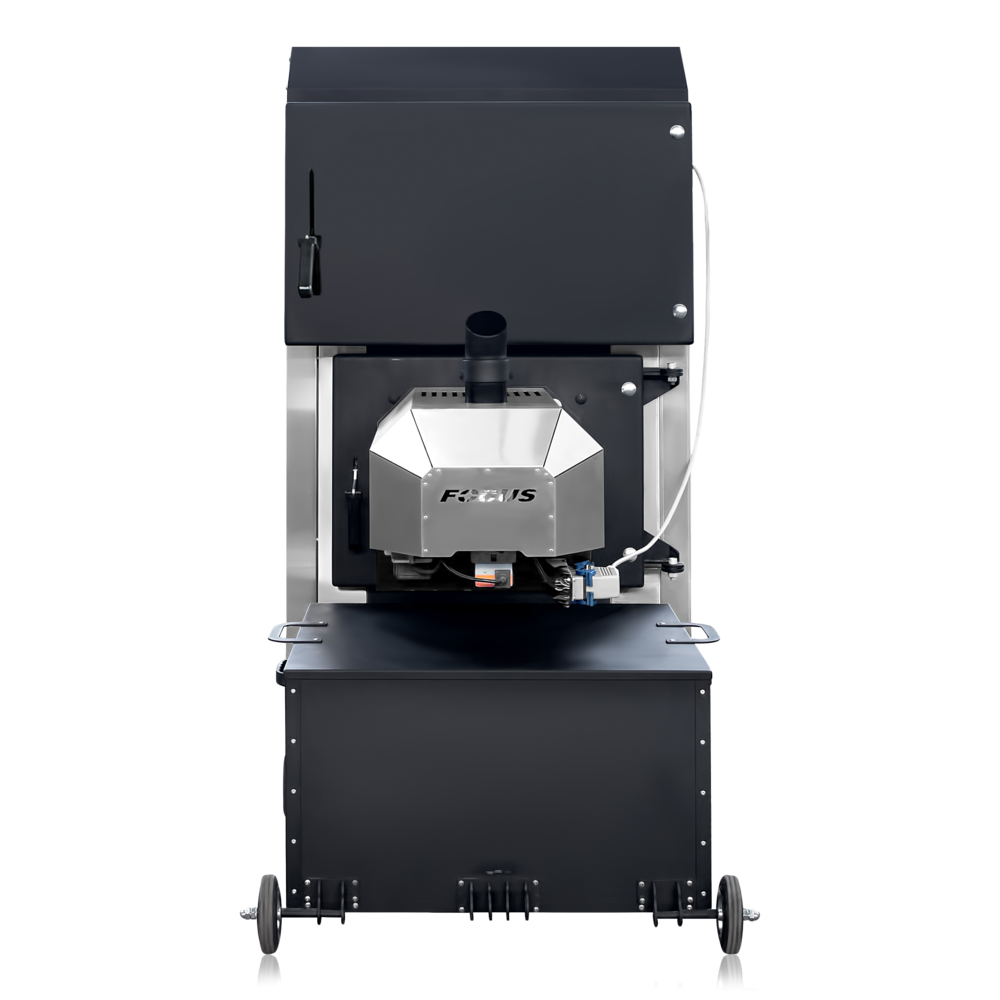

Встроенная пеллетная горелка

Пеллетная горелка TM «FOCUS», встроенная в пеллетный котел 100 кВт FOCUS, совместима как с древесной пеллетой, так и с агропеллетой с зольностью до 10%. Она работает с топливными гранулами из различных отходов, включая подсолнечник, кукурузу, гречку, рис и солому.

Преимущества встроенной горелки:

- Автоматический розжиг: обеспечивается японскими керамическими свечами для бесконтактного розжига.

- Подвижный моноколосник: ворошит горящее топливо и удаляет остатки в зольник.

- Датчики безопасности: встроенные датчики температуры и пламени контролируют работоспособность горелки и предотвращают аварийные ситуации.

- Оптимизированное сжигание: правильно подобранные пропорции первичного и вторичного воздуха способствуют эффективному сгоранию.

- Хромистое сопло: для моделей от 17 кВт до 150 кВт обеспечивает высокую устойчивость к коррозии и перегреву.

Пеллетный котел FOCUS 100 кВт является идеальным решением для отопления частных домов, небольших магазинов и удаленных объектов. Его автоматизация, высокая эффективность и удобство в обслуживании делают его выгодным выбором для тех, кто ищет надежное и экономичное отопление.

Функции и комплектация

Пеллетный котел 100 кВт FOCUS (20-100 кВт) и его функционал:

- регулировка интенсивности горения 20 кВт – 100 кВт;

- 5 уровней безопасности;

- автоматическая работа: розжиг, тушение, очистка в процессе работы, очистка от золы при гашении факельной горелки;

- шнековое золоудаление во внешний контейнер автоматически;

- очистка горелки в общую систему золоудаления автоматически;

- керамическая свеча бесшумного розжига, с дублированием свечей зажигания;

- энергопотребление от сети и солнечных панелей (800 Вт);

- PID-регулирование (возможность точного регулирования горелки в рамках технологии «умный дом»);

- подвижный, съёмный моно-колосник из хромистого сплава для механической очистки горелки;

- управление насосами (горячая вода и отопление);

- работа с комнатными терморегулирующими устройствами и интернет-модулем;

- работа с погодным регулированием;

- встроенный зольный фильтр.

Пеллетный котел 100 кВт FOCUS соответствует ГОСТ32452-2013 (EN 15270:2007). Предоставляется гарантия 12 месяцев.

Комплект поставки:

- пеллетный котел 100 кВт FOCUS в сборе с горелкой, система шнекового золоудаления;

- откатной контейнер сбора золы — комплект;

- интернет-модуль EcoNet;

- датчик погоды;

- датчик температуры дым газов;

- датчик температуры обратного контура котла;

- подающий шнековый транспортер – 2 м;

- гофрированная труба ПВХ – 1 м;

- контроллер по управлению пеллетной горелкой;

- документация.

Оборудование для пеллетных котельных

Устройства и модули, повышающие уровень автономности системы отопления:

- комплекты обвязки с трехходовым или четырехходовым клапаном интегрированные в систему управления котла;

- бункеры для хранения и подачи пеллеты;

- комнатный сенсорный регулятор EcoSter;

- дополнительные датчики температуры.

Проконсультируйтесь по особенностям развертывания отопительных контуров и подключения у наших специалистов.

Габариты

Указаны в каждой позиции отдельно.

Диаметр дымохода

250 мм

Требования к помещению котельной

При проектировании необходимо придерживаться требований:

- МДНАОП 0.001.26-96;

- ДБН В.2.5-ХХ: 20ХХ;

- СНиП 2.04.05-91 «Отопление, вентиляция и кондиционирование»;

- СНиП II-35-76 «Котельные установки».

Интересно почитать

Процесс эксплуатации пеллетной горелки в деталях

Какой твердотопливный котел купить для производства

Отзывы

Отзывов пока нет.