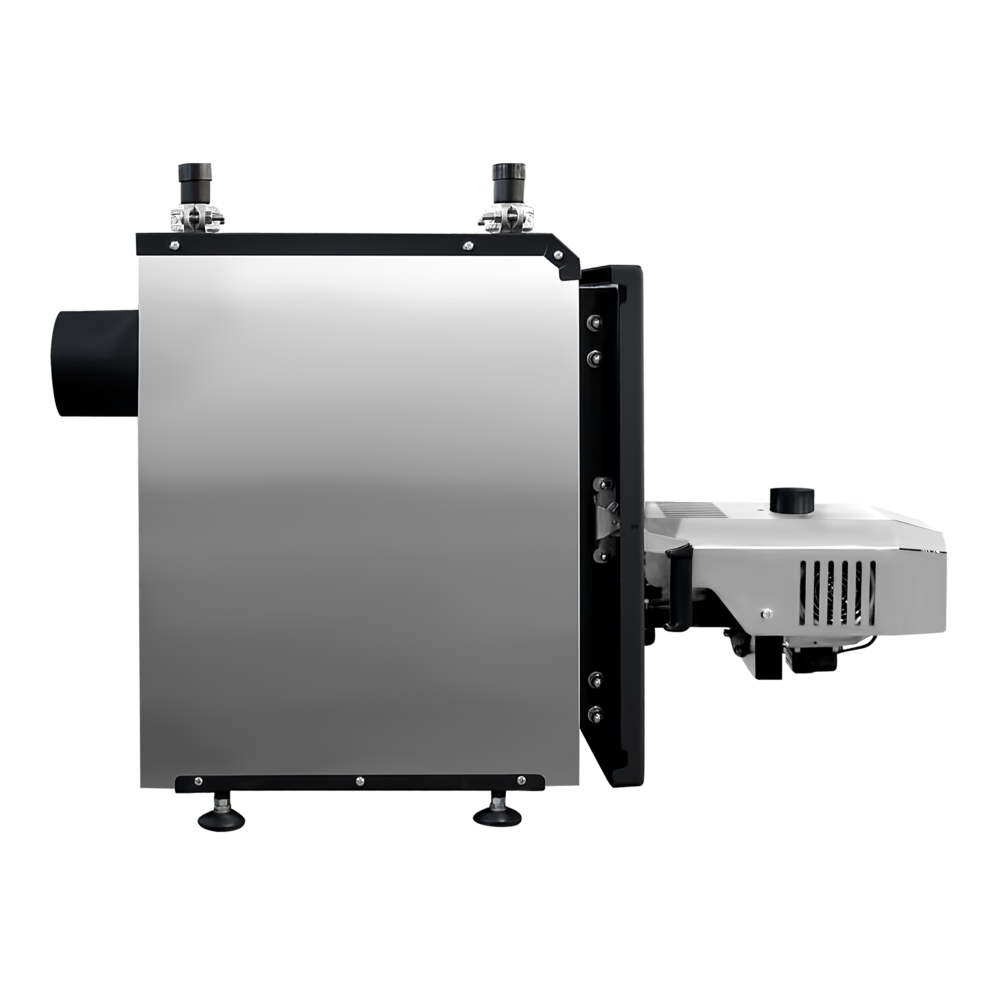

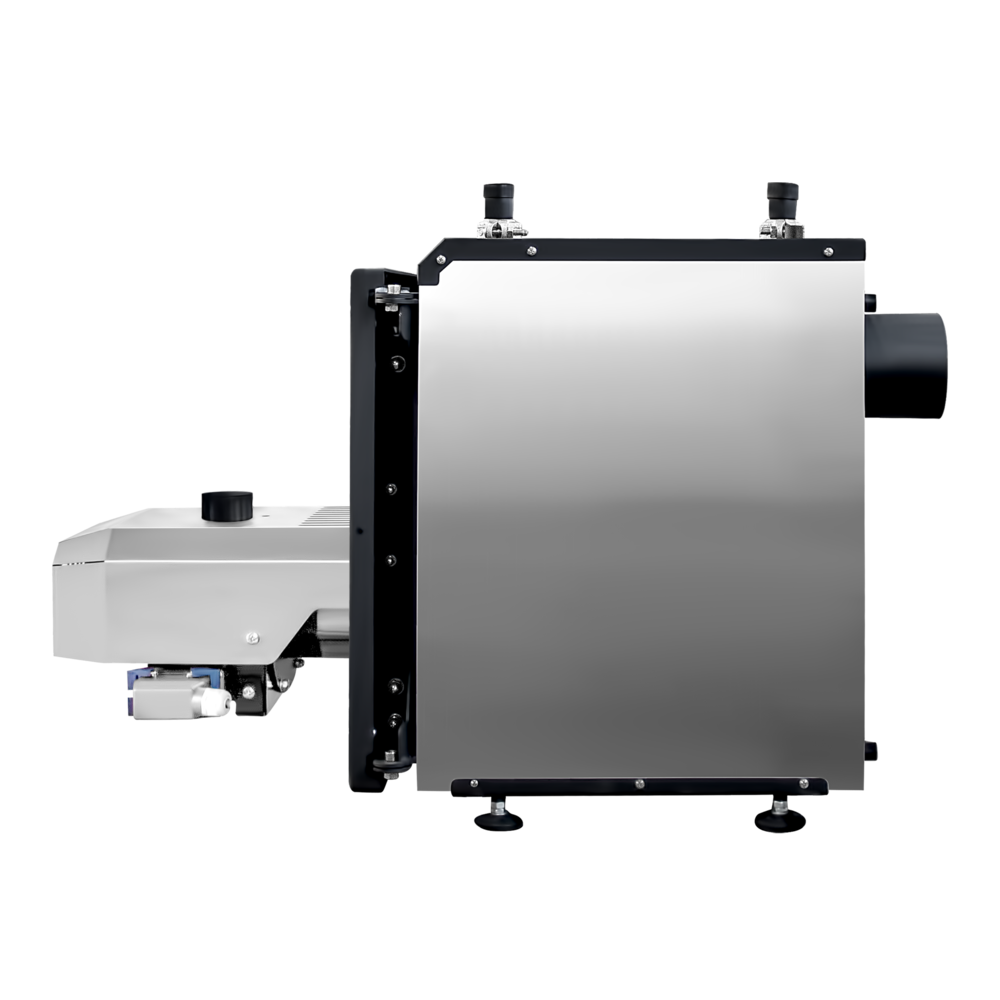

Автоматический твердотопливный котел Моно-пеллет 25 кВт FOCUS для домохозяйств

Автоматический твердотопливный котел Моно-пеллет 25 кВт FOCUS представляет собой современную и экономичную систему отопления, разработанную специально для работы на пеллетах. Он предназначен для отопления домов, небольших бизнес-помещений и производственных объектов площадью до 300-320 м² при условии хорошей теплоизоляции.

1. Основные характеристики котла

- Топливо: Работает на пеллетах — экологически чистом и доступном виде твердого топлива. Используются как древесные, так и агропеллеты с высоким содержанием золы (до 10%).

- Мощность: 25 кВт, что позволяет эффективно отапливать объекты среднего размера.

- Автоматизация: Котёл работает в автоматическом режиме, включая автоматическую подачу топлива, розжиг и контроль за процессом горения.

2. Эффективность и экономичность

Котел Моно-пеллет 25 кВт FOCUS ориентирован на максимальную эффективность теплопередачи и снижение затрат на отопление. Основное внимание уделяется правильной работе с пеллетами, что делает его особенно выгодным для домохозяйств и небольших коммерческих объектов:

- Экономия на топливе: котел Моно-пеллет 25 кВт FOCUS позволяет использовать различные виды пеллет, включая агропеллеты из отходов подсолнечника, кукурузы и других материалов, что снижает стоимость отопления.

- Автоматический контроль горения: Датчики контролируют пламя и температуру, что обеспечивает точную настройку мощности и снижение потребления топлива.

3. Конструкция и особенности теплообменника

Котел Моно-пеллет 25 кВт FOCUS оснащён гибридным теплообменником, сочетающим пластинчатую и трубчатую конструкции:

- Гибридный теплообменник: Это решение обеспечивает эффективное снятие тепла и фильтрацию золы. Пластинчатая часть отводит первичное тепловое напряжение, предотвращая точечное воздействие факела.

- Толщина стенок: Теплообменник выполнен из стали 09Г2С, толщина стенок теплообменной части — 6 мм, что гарантирует долговечность и высокую прочность.

- Большой зольник: Он рассчитан на несколько суток работы без необходимости очистки, что упрощает эксплуатацию, особенно при использовании высокозольного топлива.

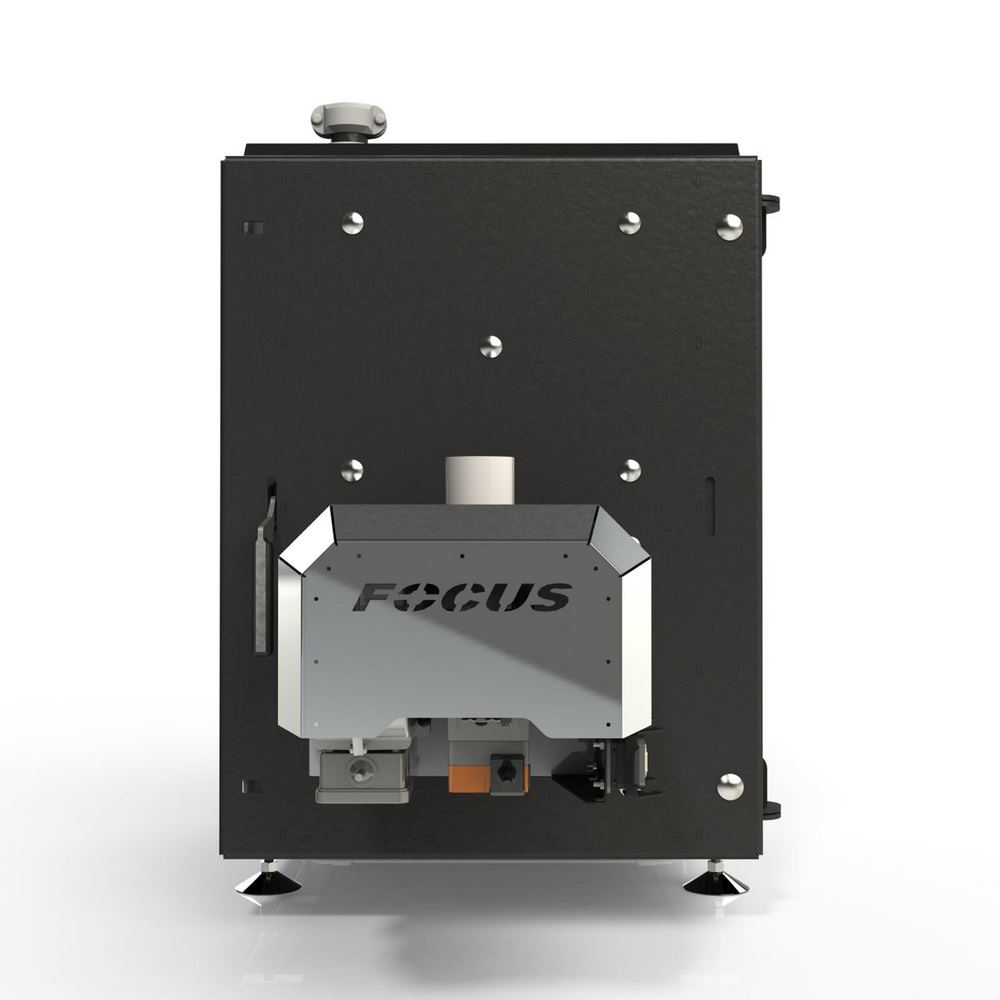

4. Горелка с самоочисткой и безопасностью

Встроенная пеллетная горелка ТМ «FOCUS» обеспечивает полную автоматизацию процесса сжигания топлива:

- Самоочистка колосника: Специальный подвижный колосник автоматически сбрасывает золу, что исключает необходимость частого обслуживания.

- Автоматический розжиг: Керамические свечи обеспечивают бесконтактный воздушный розжиг пеллет.

- Датчики безопасности: Встроенный датчик температуры шнека и инфракрасный датчик пламени следят за корректной работой горелки, автоматически отключая подачу топлива в случае аварийной ситуации.

5. Комфорт и простота обслуживания

- Интуитивно понятное управление: Котел Моно-пеллет 25 кВт FOCUS оснащён сенсорной панелью с удобным интерфейсом для настройки и контроля за работой системы.

- Удобный доступ для чистки: Широкий люк и продуманная конструкция теплообменника упрощают обслуживание и чистку, делая эксплуатацию котла более комфортной.

- Гибкость монтажа: Котёл оснащён регулируемыми петлями, что позволяет настроить дверь для плотного прилегания. Возможно изменение стороны открытия дверей.

6. Преимущества при работе на агропеллетах

Котел Моно-пеллет 25 кВт FOCUS способен работать на агропеллетах с зольностью до 10%, что делает его идеальным решением для мест, где древесные пеллеты могут быть дороже или труднодоступны. Это существенно расширяет доступность топлива и снижает затраты на отопление.

Автоматический котел Моно-пеллет 25 кВт FOCUS — это надежное и экономичное решение для отопления домов и малых коммерческих объектов. Его автоматизация, высокая производительность и возможность использования широкого спектра пеллет делают его выгодным вариантом для тех, кто ищет эффективное и удобное в эксплуатации оборудование для отопления.

Функции и комплектация

Функционал пеллетного котла Моно-пеллет (5-30 кВт):

- регулировка мощности в диапазоне 5 кВт – 30 кВт;

- площадь поверхности теплообменника 2.2 м2;

- 5 уровней безопасности;

- автоматическая работа: розжиг, тушение, очистка;

- керамическая зажигалка;

- низкое энергопотребление (без учёта авто розжига — 40Вт) – может работать от аккумулятора и солнечной панели;

- PID-регулирование (возможность точного регулирования горелкой, в том числе, в рамках технологии «умный дом»);

- подвижный колосник для механической очистки горелки;

- управление насосами (ГВС и отопление);

- работа с комнатным термостатом и интернет-модулем

- работа с погодным регулированием.

Пеллетный котел Моно-пеллет 25 кВт FOCUS соответствует ГОСТ32452-2013 (EN 15270:2007). Предоставляется гарантия 12 месяцев.

Комплект поставки

- твердотопливный котел Моно-пеллет 25 кВт FOCUS в комплексе с горелкой;

- шнековый транспортер 2 метра;

- гофрированная труба ПВХ – 1 м;

- контроллер по управлению пеллетным котлом;

- документация.

Оборудование для пеллетных котельных

Устройства и модули, повышающие уровень автономности системы отопления:

- комнатный сенсорный регулятор EcoSter;

- дополнительные датчики температуры.

Проконсультируйтесь по особенностям развертывания отопительных контуров и подключения у наших специалистов.

Габариты

Диаметр патрубка выхода дымохода

160 мм.

Требования к помещению котельной

При проектировании необходимо придерживаться требований:

- МДНАОП 0.001.26-96;

- ДБН В.2.5-ХХ: 20ХХ;

- СНиП 2.04.05-91 «Отопление, вентиляция и кондиционирование»;

- СНиП II-35-76 «Котельные установки».

Интересно почитать

Процесс эксплуатации пеллетной горелки в деталях

Какой твердотопливный котел купить для производства

Отзывы

Отзывов пока нет.