Система пневмоочистки для котлов FOCUS: стабильное повышение КПД

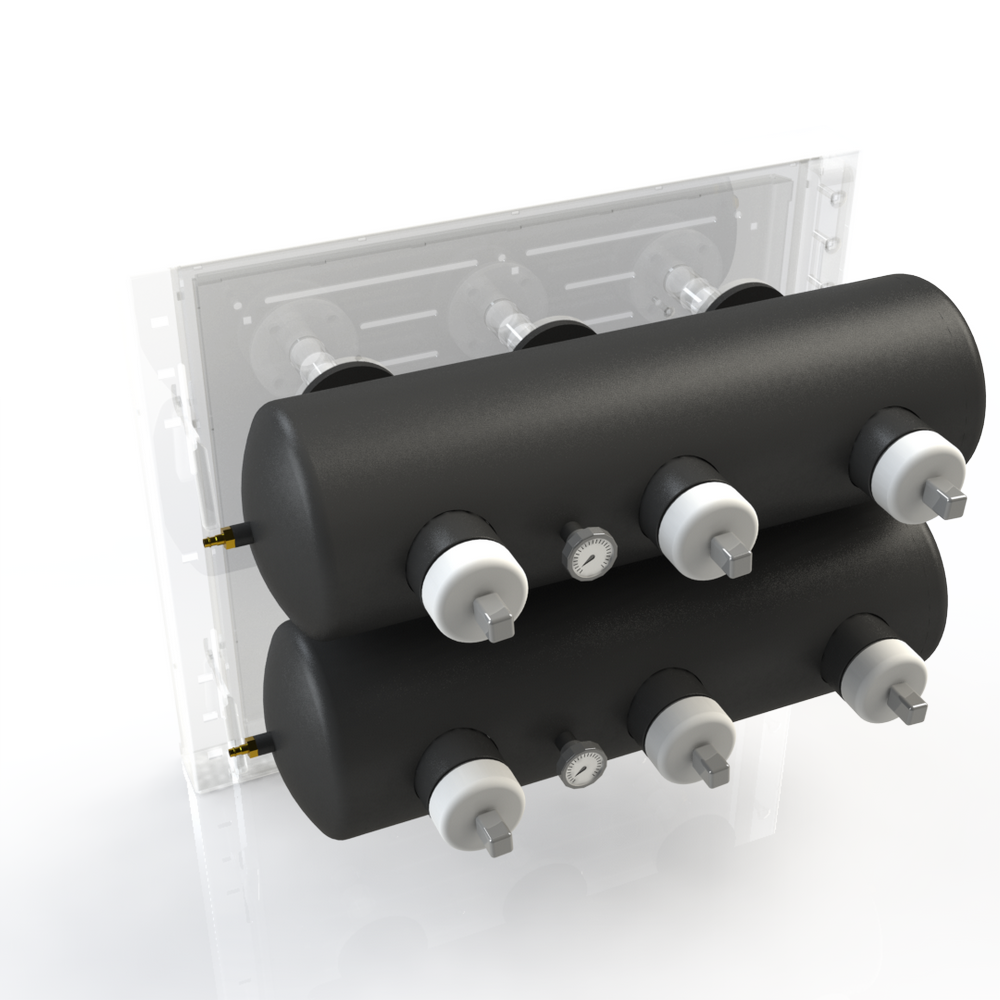

В процессе эксплуатации теплообменники котлов накапливают золу, что снижает эффективность их работы из-за увеличения аэродинамического сопротивления. Это приводит к снижению КПД и уменьшению мощности котла. Ручная очистка требует полной остановки оборудования, что неудобно как для потребителей, так и для обслуживающего персонала. Система пневмоочистки для котлов с очисткой пневмоспособом решает эту проблему.

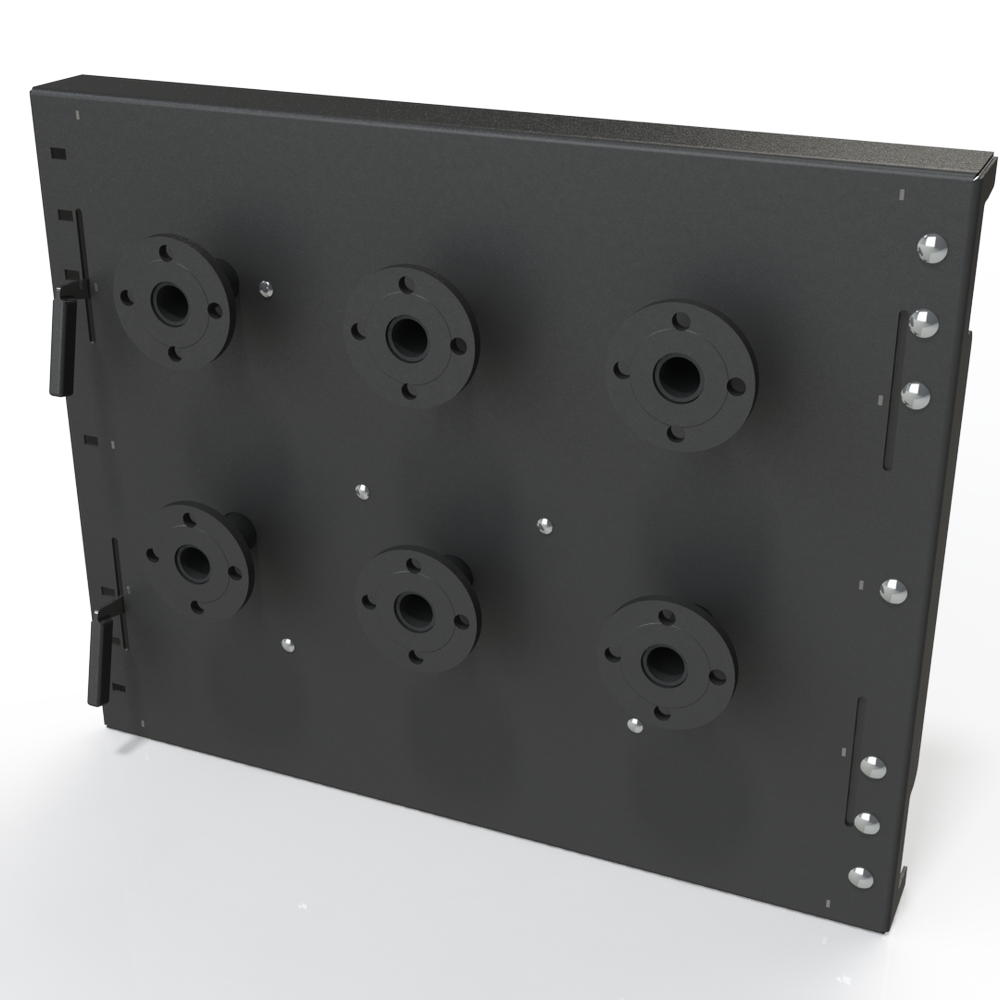

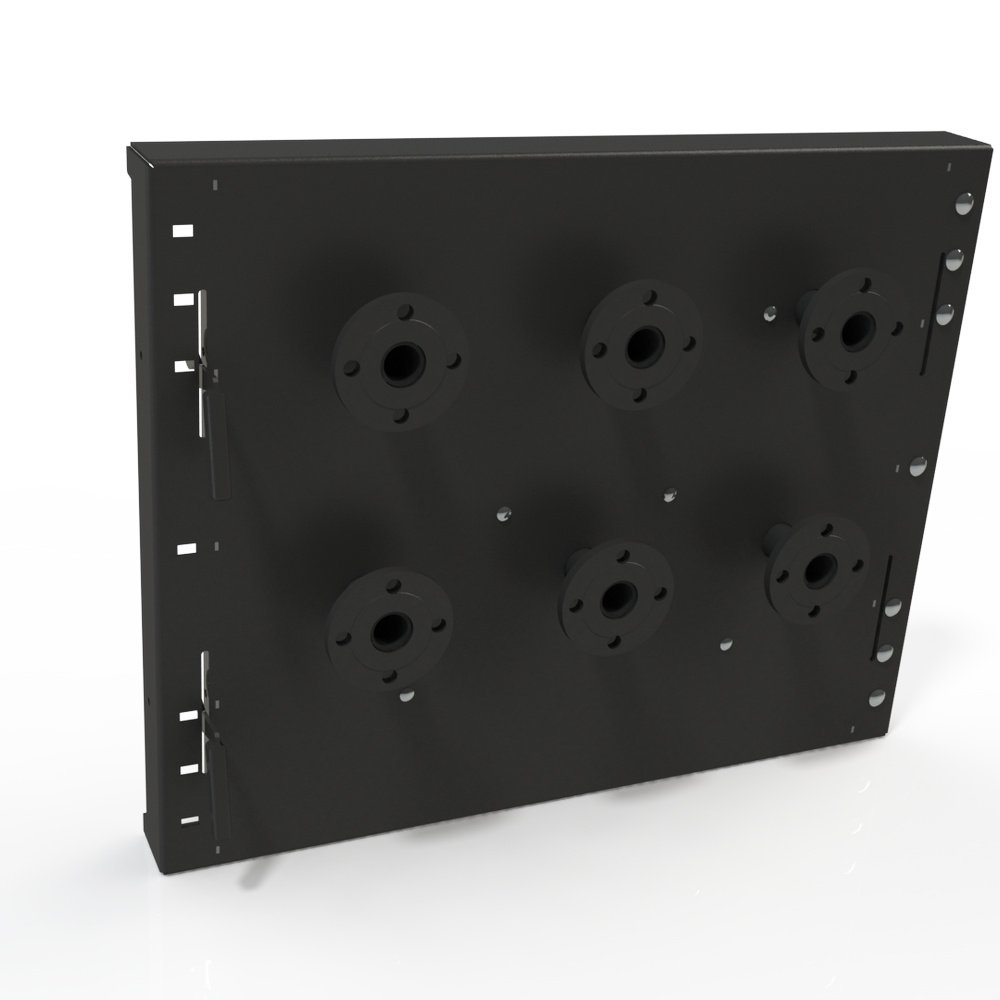

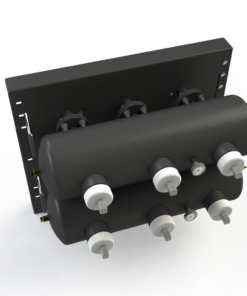

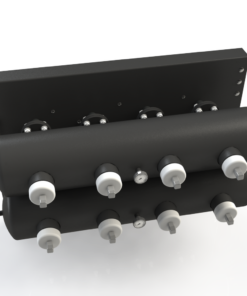

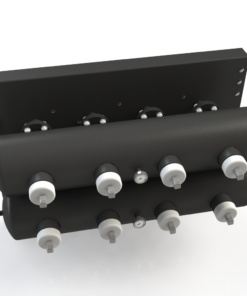

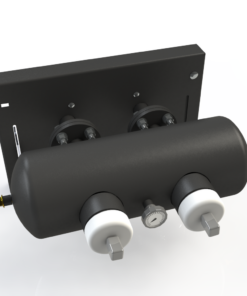

Система пневмоочистки для котлов FOCUS 400 кВт автоматизирует этот процесс, позволяя очищать теплообменник без необходимости остановки котла. Она использует сжатый воздух для удаления отложений золы, накапливающихся внутри теплообменника, что способствует поддержанию оптимальной эффективности и увеличению времени непрерывной работы котла. Процесс очистки включает в себя регулярную продувку воздухом под высоким давлением, что помогает смещать и удалять накопившиеся остатки.

Система пневмоочистки для котлов FOCUS:

- увеличивает временные промежутки между полными очистками котла;

- продлевает время беспрерывной работы теплогенерации и сводит очистку к техобслуживанию;

- обеспечивает высокую эффективность очистки от отложений;

- уменьшает до минимума потребность в ручном обслуживании.

Эта система для котлов до 400 кВт позволяет значительно увеличить интервалы между очистками и снижает необходимость в ручном труде, подходит как для твердотопливных котлов FOCUS, так и для оборудования других производителей.

Отзывы

Отзывов пока нет.