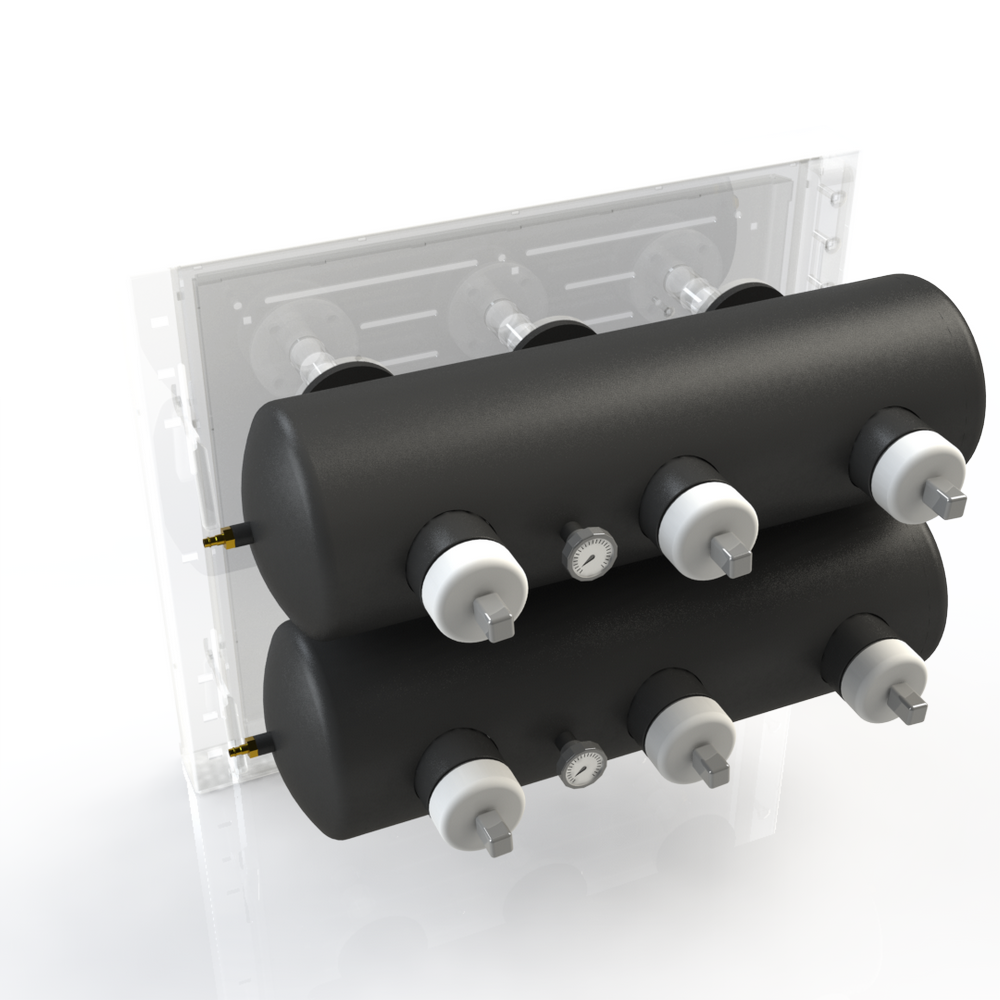

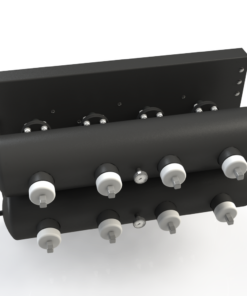

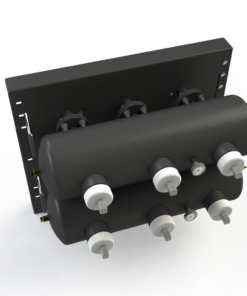

Система пневмоочистки котла на 300-400 кВт для самостоятельной установки

Продукты сгорания имеют свойство накапливаться на стенках котла, что снижает его теплопроводность и, как следствие, уменьшает КПД. Оседание золы увеличивает аэродинамическое сопротивление, что негативно сказывается на эффективности работы системы отопления. Очистка от сажи — процесс обязательный, но весьма трудоемкий, требующий полной остановки котла. Это особенно неудобно в холодное время года и затрудняет эксплуатацию котельной при самостоятельном обслуживании.

Система пневмоочистки котла на 300-400 кВт автоматизирует этот процесс, используя сжатый воздух для очистки стенок и теплообменников от золы и отложений. Ее применение позволяет свести к минимуму количество необходимых полных сеансов техобслуживания, делая очистку быстрой и менее трудоемкой. Оборудование ФОКУС выполняет эту задачу автоматически, в нужные интервалы времени, облегчая эксплуатацию котла.

Система пневмоочистки котла:

- поддерживает уровень КПД котла за счет удаления продуктов сгорания со стенок теплообменника;

- позволяет использовать непрерывную теплогенерацию во время низких температур воздуха на улице;

- удаляет отложения на конструкции и элементах камеры сгорания;

- нет необходимости в ручном труде.

Эта система пневмоочистки котла на 300-400 кВт позволяет значительно увеличить интервалы между очистками и снизить необходимость в ручной работе, подходя как для твердотопливных котлов FOCUS, так и для котлов других производителей.

Отзывы

Отзывов пока нет.