Система пневмоочистки для котлов 20-50 кВт для самостоятельной установки

Система пневмоочистки для котлов 20-50 кВт:

- поддерживает высокий уровень КПД, удаляя продукты сгорания с теплообменных поверхностей;

- обеспечивает непрерывную теплогенерацию, что особенно важно в условиях низких температур;

- эффективно устраняет отложения на конструктивных элементах камеры сгорания;

- минимизирует потребность в ручной очистке.

Система пневмоочистки для котлов 20-50 кВт значительно увеличивает интервалы между обслуживанием котлов в частных домах и снижает трудозатраты на очистку, совместима как с твердотопливными котлами FOCUS, так и с моделями других производителей.

Пневмоочистка котлов: преимущества и особенности

Пневмоочистка котлов – это современная технология автоматической очистки теплообменника, используемая в пеллетных котлах. Этот процесс позволяет удалять накопившуюся пыль, золу и отложения с поверхностей теплообмена, что существенно повышает эффективность работы котла и продлевает срок его эксплуатации. Пневмоочистка особенно актуальна при использовании топлива с высокой зольностью, например, агропеллет.

Как работает пневмоочистка?

Система пневмоочистки для котлов 20-50 кВт использует сжатый воздух, подаваемый через специальные форсунки, которые размещены внутри теплообменника. В определенные промежутки времени (настраиваемые параметры), система автоматически включает пневмоудары, которые «сдувают» зольные отложения с поверхностей теплообменника. Освободившаяся зола собирается в зольник, откуда удаляется при помощи шнекового золоудаления или вручную, в зависимости от модели котла.

Преимущества пневмоочистки

- Автоматизация процесса: Система пневмоочистки для котлов 20-50 кВт полностью автоматизирована и не требует участия пользователя, что значительно снижает трудозатраты на обслуживание котла.

- Повышение КПД: Регулярная очистка теплообменника обеспечивает постоянную высокую эффективность передачи тепла, поскольку исключает появление толстого слоя золы, который снижает КПД.

- Продление срока службы: Отсутствие загрязнений предотвращает перегрев и преждевременный износ элементов котла, что продлевает его срок службы.

- Минимизация остановок работы: Благодаря автоматической очистке, котел может работать дольше без необходимости частых остановок для ручной чистки, что особенно важно для объектов с непрерывным тепловым режимом.

- Эффективное использование агропеллет: Технология пневмоочистки особенно полезна при использовании агропеллет с высоким содержанием золы, обеспечивая их сжигание без проблем с отложениями.

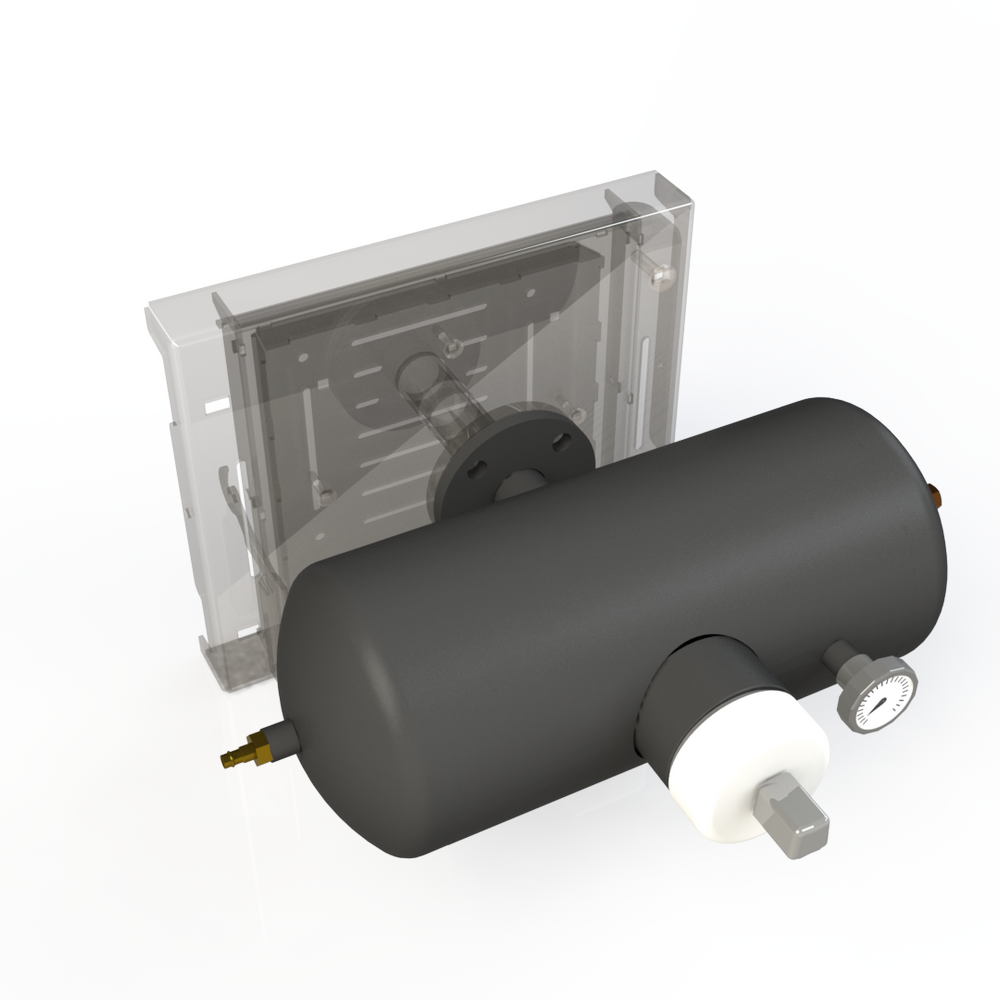

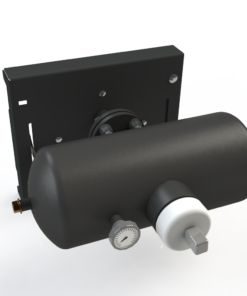

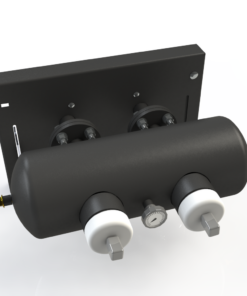

Ключевые элементы системы пневмоочистки

- Компрессор: Обеспечивает подачу сжатого воздуха для очистки.

- Ресивер: Накопительный бак для сжатого воздуха, обеспечивающий постоянное давление для эффективной очистки.

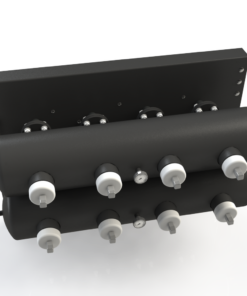

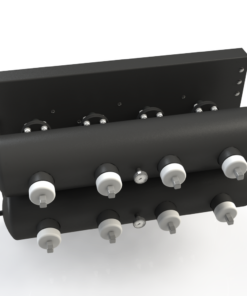

- Электроклапаны: Управляют подачей воздуха в форсунки по заданной программе.

- Очистные форсунки: Устанавливаются в ключевых точках теплообменника, направляя воздушные потоки для удаления золы.

Пневмоочистка котлов – это инновационное решение для владельцев пеллетных котлов, которые стремятся обеспечить максимальную производительность и экономичность своего отопительного оборудования. Используя эту технологию, вы получите стабильное и эффективное тепло с минимальными затратами на обслуживание и эксплуатацию.

Отзывы

Отзывов пока нет.