Контроллер для систем пневмоочистки FOCUS при самостоятельной установке решит проблемы очистки котла

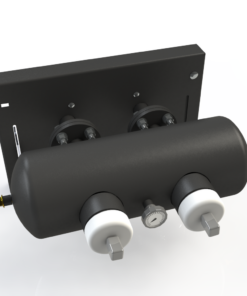

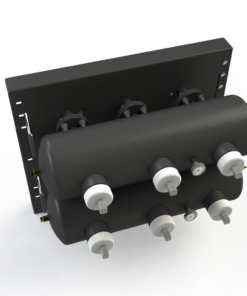

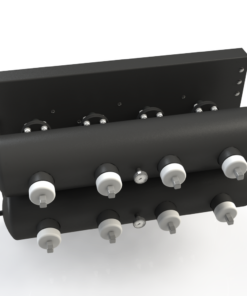

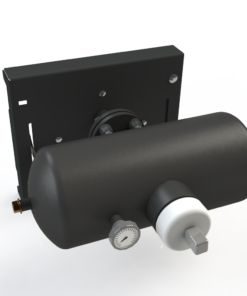

Контроллер для систем пневмоочистки FOCUS — это специализированное устройство автоматического управления системой очистки теплообменников и горелок от золы и других твердых отложений, предназначенное для установки на твердотопливные котлы. Он управляет подачей сжатого воздуха в пневматическую систему очистки, обеспечивая регулярное удаление отложений с поверхностей, что способствует поддержанию высокого КПД оборудования. Предложенный контроллер для систем пневмоочистки может работать в автономном режиме или интегрироваться с системой управления котлом, обеспечивая синхронизацию процессов очистки с его работой.

Почему важно чистить котел, и лучше чистить его автоматически

В процессе работы котлов теплообменники постепенно накапливают отложения золы, что вызывает сопротивление воздушному потоку и снижает эффективность теплообмена. Это приводит к уменьшению мощности и снижению КПД. Ручная очистка требует полной остановки работы котла, что неудобно для потребителей и персонала. Контроллер для систем пневмоочистки предназначен для управления очисткой котла пневмоспособом.

Система пневмоочистки решает эту проблему автоматически, без необходимости остановки котла. Она использует сжатый воздух для удаления отложений внутри теплообменника, значительно повышая эффективность работы оборудования. Устройство монтируется в переднюю часть теплообменника и периодически продувает внутренние компоненты котла воздухом под высоким давлением, что помогает удалять накопившуюся золу.

Контроллер для систем пневмоочистки FOCUS управляет интервалами активации пневматических клапанов, отвечающих за подачу воздуха для очистки. Он позволяет настраивать частоту срабатывания, адаптируя процесс очистки под конкретные условия эксплуатации.

Отзывы

Отзывов пока нет.