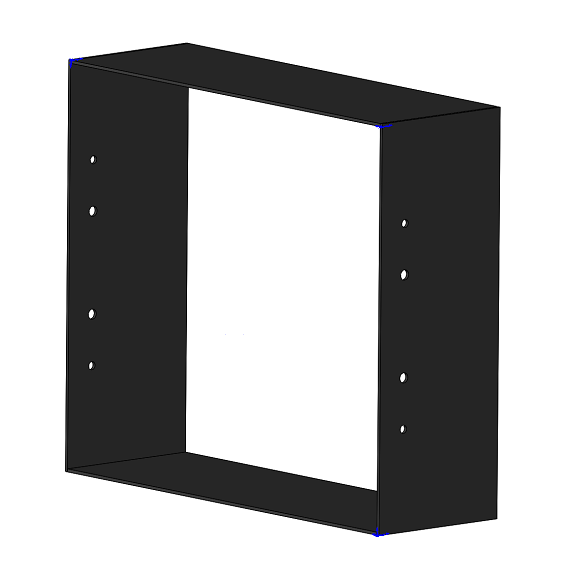

Лутка ЛТ-150 для котлов 150 кВт: модернизация и ремонт

Лутка ЛТ-150 для котлов 150 кВт представляет собой важный компонент, предназначенный для модернизации твердотопливных котлов и тепло-генераторов. Она позволяет адаптировать существующее оборудование для работы с современными пеллетными горелками или дверями для ручной загрузки топлива. Это решение значительно улучшает характеристики отопительной системы, повышает её эффективность и упрощает процессы эксплуатации.

Модернизация котла с луткой ЛТ-150

Модернизация котла — это процесс обновления устаревшего оборудования, позволяющий повысить его производительность и снизить эксплуатационные затраты. Установка лутки ЛТ-150 дает возможность перевести котлы на использование пеллетного топлива, что делает систему отопления более экологичной и экономически выгодной.

Ключевые особенности лутки ЛТ-150:

- Адаптация к современным технологиям

Лутка ЛТ-150 для котлов 150 кВт идеально подходит для установки пеллетных горелок и дверей, что позволяет легко обновить старые котлы и теплогенераторы. Это делает её универсальным решением для многих моделей оборудования. - Гибкость в установке

Благодаря своей конструкции, лутка может быть использована для различных типов установки, будь то дверь для ручной загрузки или пеллетная горелка. Это расширяет возможности применения лутки в разных системах отопления. - Долговечность и устойчивость

Изготовленная из прочной конструкционной стали, лутка ЛТ-150 для котлов 150 кВт обладает высокой термостойкостью и способностью противостоять механическим нагрузкам, что обеспечивает её надёжную работу на протяжении долгого времени. - Эффективная теплоизоляция

Лутка ЛТ-150 для котлов 150 кВт обеспечивает плотное соединение с дверью котла, что помогает минимизировать потери тепла и улучшает энергоэффективность системы. Это особенно важно при использовании пеллет, так как стабильные условия горения способствуют лучшему сжиганию. - Простота монтажа и обслуживания

Лутка ЛТ-150 легко устанавливается благодаря наличию крепёжных отверстий. Она позволяет обеспечивать доступ к горелке и котлу для проведения регулярного обслуживания, чистки и ремонтов.

Технические характеристики:

- Материал: Конструкционная сталь, обладающая высокой прочностью.

- Толщина: 6 мм, что обеспечивает дополнительную надёжность.

- Совместимость: Подходит для различных моделей твердотопливных котлов.

- Тип монтажа: Устанавливается как с дверями для ручной загрузки, так и с пеллетными горелками.

- Устойчивость к температурам: Способна выдерживать длительные термические нагрузки.

Преимущества модернизации с помощью лутки ЛТ-150:

- Снижение затрат на отопление

Переход на пеллетное топливо помогает существенно уменьшить расходы на отопление, так как пеллеты обладают высокой теплотворной способностью и низкой стоимостью. - Экологическая безопасность

Использование пеллет значительно снижает выбросы вредных веществ в атмосферу, что делает систему отопления более устойчивой к экологическим требованиям. - Увеличенная энергоэффективность

Улучшенные теплоизоляционные свойства и герметичность лутки ЛТ-150 способствуют более эффективному использованию тепла внутри котла. - Комфорт в эксплуатации

Модернизация оборудования с использованием лутки ЛТ-150 делает систему отопления более удобной за счёт автоматизации процессов, что сокращает потребность в ручной загрузке топлива.

Комплектация:

- Лутка ЛТ-150 для котлов 150 кВт.

- Чертёж для установки.

- Набор крепёжных элементов для монтажа.

Лутка ЛТ-150 является идеальным решением для модернизации твердотопливных котлов, обеспечивая их соответствие современным стандартам и требованиям. Установка этой лутки позволяет повысить эффективность работы системы отопления, сделать её более экономичной и удобной в эксплуатации.

Отзывы

Отзывов пока нет.